Author: Sofie Lodens, BBEPP

Bio Base Europe Pilot Plant (BBEPP) is an independent, state-of-the-art facility that operates from laboratory level to multi-ton scale. Bio Base Europe Pilot Plant is a service provider for process development, scale-up and customised manufacturing of bio-based products and processes. A wide and flexible spectrum of modular unit operations combined with the experience of our highly competent engineers and technicians enables us to turn your biobased laboratory protocol into a viable industrial process.

In the Bionanopolys project, BBEPP aims to produce a glucose hydrolysate from spruce pulp with the highest possible glucose content in order to enable other consortium partners to produce bioplastics (in particular PHA) with microorganisms that use this glucose hydrolysate as a substrate.

For this purpose, BBEPP had to test available protocols and transform the process from initial lab experiments to the pilot scale.

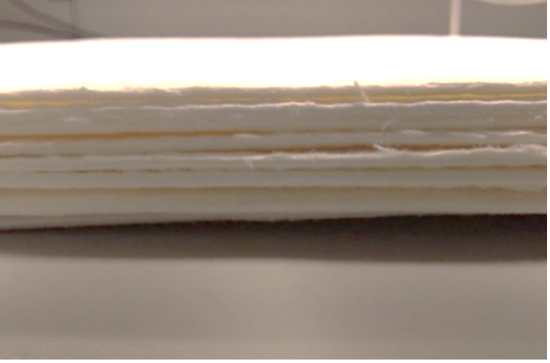

The aim was to produce at least 150kg of sugar hydrolysate with 50% glucose starting from 500kg of spruce pulp sheets. This came along with a couple of challenges: First of all, the viscosity of the spruce pulp mixed with water was shown to be more difficult at higher scale than in the lab, and we already had to add enzyme when almost half of the 500kg total material were added.

Also the filtration step showed to be challenging, i.e. without a precoat, the solids were retained in the filtrate, thus we had to add this. Yet after this a feed flow drop was observed and even after restart of the equipment this was again the case. Therefore we switched to a bigger plate filtration unit and after this the filtration wend smoothly for the rest of the batch.as we had to change equipment during the run. After this, the filtration ran smoothly and after polishing and concentration we obtained 369 kg of sugar stream with a very nice glucose concentration of 460 g/L.

The resulting glucose hydrosylate was transferred to Bionanopolys’ partner Biotrend and this material was used as substrate in PHA production experiments. In a second pilot run, the concentration and glucose yields turned out to be very satisfying. It was investigated whether we could further stretch the enzymatic hydrolysis to obtain even higher glucose concentrations. The results and data are currently still being processed, but the initial results are promising.

Picture credits: BBEPP