Pilot plants &

other services implemented

Network 1: Starting from biomass

Technical Services for Nanoadditives and Raw Materials

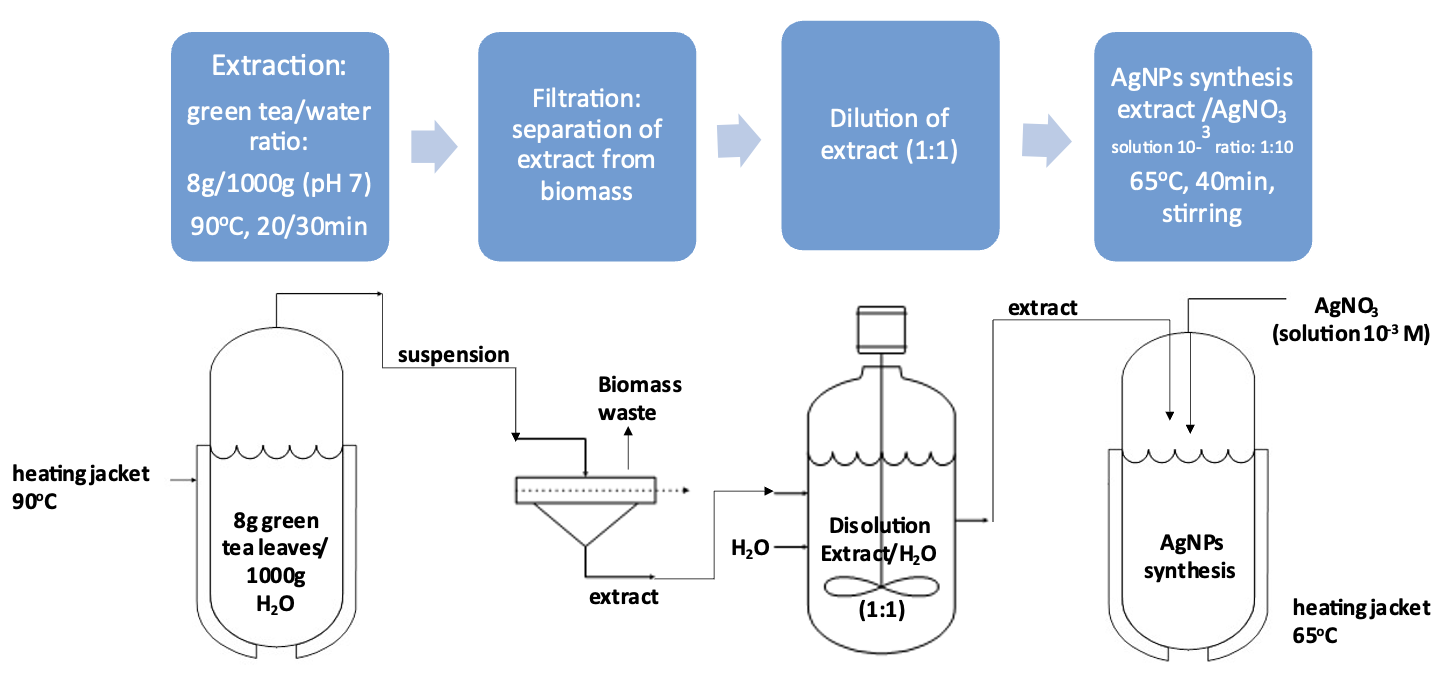

Network 1 will oversee the selection and logistics of biomass, its extraction of raw materials and production of different nanoadditives by the treatment and/or reaction of these raw materials.

Expertise and Capabilities:

- Biomass pre-treatment including enzymatic hydrolysis

- Characterization of biomass and advice on biomass sourcing and storage

- Cooking and bleaching of cellulose pulp

- Production of lignin from black liquors

Infrastructure:

- Multipurpose bioprocessing pilot plant with stainless steel, steam-sterilizable fermenters of 10L, 50L, 200L

- Pilot scale downstream processing equipment

- Process monitoring capabilities (fermentation and DSP, integrated control software)

Application field:

- Sugar conversion by fermentation

- Fibres for papers/boards, CMF/CNF

- Materials for textile, cosmetic, packaging, biomedical applications, automotive, structural applications, agriculture,…

Expertise and Capabilities:

- Production of CNF by mechano-enzymatic pretreatment followed by homogenization or twin-screw extrusion

- Production of CNF by enzymatic or chemical treatment and mechanical grinding

- Production of CNC by acid hydrolysis of cellulose

- Production of nano-lignin through the application of mechanical treatment to lignin

Infrastructure:

Twin screw extruder with following characteristics:

- Evolum 32 bivis extruder (Clextral)

- Flow: 5 to 20 kg/h in equivalent dry matter content

- Screw elements diameter: 32mm

- Total length of barrel: 1280 mm

- Motor power: 50 kW

- Rotation speed: 300 – 1200 rpm

- Temperature regulation of the barrel: 30 to 300°C

Application field:

- Cosmetic

- Packaging

- Coatings, paintings

- Building block chemicals for adhesives, carbon fibres, phenol sources

Expertise and Capabilities:

- Synthesis and development of tailor-made block copolymers from biomass

- Biochemicals from biomass, strain engineering, cultivation of microorganisms

- Fermentation process development, optimization and scale-up

Infrastructure:

- Polymerization reactors (3L, 10L and 15L)

- Multipurpose bioprocessing pilot plant with stainless steel, steam-sterilizable fermenters of 10L, 50L, 200L

- ilot scale downstream processing equipment

- Process monitoring capabilities (fermentation and DSP, integrated control software)

- Distillation column to perform polycondensation reactions

- Inline viscosimeter

Application field:

- Food and cosmetic packaging

- 3D printing applications

- Sugar conversion by fermentation

- Materials for textile, cosmetic, packaging, biomedical applications, automotive, structural applications, agriculture

Benefits for SMEs and companies:

- Specific additive solutions with improved functionalities for food and cosmetic packaging industry

- Green chemistry routes for preparing sustainable additives

Expertise and Capabilities:

- Development and production of functional nanocapsules at pilot scale through nanoemulsion process. Characterization of the product and delivery of the product in water-based dispersions or in dried state.

- Development of functional (sub)-microcapsules by spray drying

Infrastructure:

- Jacketed glass reactor with a maximum volume of 10 L equipped with a condenser that also works under low pressure conditions, and several accessories to ensure the preparation of the nanoemulsion and the efficiency of downstream steps.

Application fields:

- To be incorporated into polymer-based matrices, such as thermoplastic compounding and/or liquid coating formulations (water or solvent based)

- To be directly deposited or coated on surfaces: plastic, textile, paper substrates.

Benefits for SMEs and companies:

- Nanocapsules with (bi)functionality and suitable for different applications, namely packaging (e.g. extension of shelf-life), textile (e.g. cosmetotextiles) and cosmetic applications;

- Scalable process;

- Green chemistry approach – use of green solvents;

- Environmentally friendly nanomaterials – low environmental impact process and compostable nanomaterial.

Network 2: Starting from nanomaterials

Technical Services for Bionanocomposites

Network 2 is the group for the production of bionanocomposites and the pre-treatment needed to process the bionanomaterials that will be introduced in these bionanocomposites.

Expertise and Capabilities:

- Functionalization of nanoparticles to improve compatibility with the biopolymers

- Chromatogeny grafting to bring hydrophobic properties to hydrophilic substrates

- Deposition of metallic nanoparticles onto nanoclay or CNF

- Spray drying systems to obtain nanoadditives in powder form

- Grinding and sieving of nanoadditives

Infrastructure:

- Tubular furnace for gas-solid reactions (max. Tª 1200ºC)

- ATEX reactor (100 L, 20/230ºC, 3 bars) with pHmeter and conductivity to better control the reactions

- ATEX reactor (100 L, 80ºC, 3 bars)

- ATEX reactor (20 L, -10/250ºC, 10 bars)

- Spray drier for water-based nanodispersions

Application fields:

- To be incorporated into thermoplastic polymeric matrices for food and cosmetic packaging

- Corrugated board resistant to rain/water

- Health and medical papers

- Technical paper for industry and buildings; filters, membranes

- Papers for agriculture

- Baking papers

- Sacks, bags, wrapping papers, lids, box boards, trays, cups, plates

- Oil absorbent paper

Benefits for SMEs and companies:

- Green chemistry approach

- More cost efficiency

- Environmentally friendly nanomaterials

Expertise and Capabilities:

- Compounding process of biopolymers with nanoadditives; gravimetric & volumetric feeding

- Chemical modification of biopolymers by grafting nanomaterials through reactive extrusion (Packaging/Automotive/Textile & Agriculture)

Infrastructure:

- Laboratory extruder (proof of concept experiments)

- Reactive extrusion pilot plant (scale up)

- Reactive / Compounding extrusion line by twin-screw extruder (LEISTRITZMICRO 27 GL-36D)

- MiniTwin gravimetric feeder (specialized in low feeding range capacities)

- In-line rheometer

- In-line spectroscopic devices

Application fields:

- Packaging

- Textile,

- Automotive

- Construction

- Raw material providers for plastic industry

- Biomedical applications

- Agriculture

Benefits for SMEs and companies:

- REX technology provides stable and irreversible covalent bonds, achieving a uniform distribution of functional moieties into the polymer matrix, and avoiding particle aggregation, migration and leaching.

- One-step solvent free route to produce novel and high-performance materials with new functionalities

- Mild and environmentally friendly conditions

- Tailored configuration by using a processing simulation software

- Preparation of nanodispersion with low required amount of nanoadditives

- Control in real-time of the dispersion grade by rheological and spectroscopic measurements through the in-line monitoring devices

Expertise and Capabilities:

- Preparation of stable dispersions of nanoadditives; CNF, CNC, nanoclays in coating

- Dispersion nanoparticles by in situ polymerization

- Polymer-based dispersions with functional nanocapsules

Infrastructure:

- Synthesis reactor Kiloclave Type 3E/2l/60bar (Büchi AG) (Vessel Volume 2 litres)

- Jacketed glass reactor with a maximum volume of 10 L equipped with accessories to ensure the preparation of suitable nanodispersions such as mechanical or ultrasonication homogenization with recirculation of liquid media systems.

- AITEX reactor (100 L, 20/230ºC, 3 bars) with an ultra-high shear mixer to get a high dispersion grade and a pH meter to better control dispersion and stability of the polymeric nanodispersions

Benefits for SMEs and companies:

- Condensation and addition polymerization by synthesis, to development and production of new formulations to obtain biopolymers pellets with bioadditivesforcustomized applications.

- Control in real-time of the pH of the nanodispersions

- Stable bionanodispersion to be used as coatings on various substrates: paper, plastic, textile.

Network 3: Starting from bionanocomposites

Technical Services for Bionanoproducts

Network 3 includes pilot plants to obtain bionanoproducts from the different bionanocomposites of network 2.

Expertise and Capabilities:

- Production of monolayer films of biopolymers with bioadditives

- Production of multilayer films: co-extrusion process up to 5 layers

- Rigid packaging prototypes obtained by thermoforming

Infrastructure:

- Monolayer film extrusion, with mono-screw extruder and calendering system (COLLIN E30P).

- Flat sheet die has 300 mm width

- Variable thickness (20 µm- 300 µm), depending on feeding/roll up ratio.

- Capacity ≈ 3 m/min

Application field:

- Packaging/ Food Packaging

- Agriculture

Benefits for SMEs and companies:

- Production of thin monolayer bio-films,with tunable properties, based on biopolymer matrices reinforced with different nano-additives.

Expertise and Capabilities:

- Production and evaluation of paper containing nanoadditives in mass

- Wet-lamination of CNF on paper and cardboard

- Production of CNF self-standing films (lab and pilot scale)

Application fields:

Packaging

Expertise and Capabilities:

- Meltblown nonwoven production and consulting services

- Fibre nonwoven production and consulting services

- Monofilament and multifilament melt spinning

- Functionalized knitted textile structure

- Hot-melt lamination

- Knife-coating (on air and on cylinder) system and padding (foulard) system

- Nanobubbles for finishing and dyeing

- Spray cabinet: functional coatings for added-value fabric and nonwoven substrates

Infrastructure:

Meltblown plant (Reifenhäuser Reicofil GmbH & Co. KG):

- Extrusion non-woven line with a working width of 60 cm

- Raw material: PP, PBT, PE, PC, TPU, bio-polymers

- Filament fineness: < 1µm to 10 µm

- Throughput of 10 kg polymer granulate per hour,

- Multirow nozzle unit,

- Electro charging unit used for online surface modification of filaments during the meltblown process.

Fibre nonwoven line (DILO Systems GmbH):

- Working width from 100 up to 240 cm, working speed max. 10 m/min,

- Processing of natural and biobased synthetic fibres ranging from 1 – 28 dtex fibre fineness and 40 to 80 mm fibre length,

- Mass per unit area of fibre nonwovens between 50 – 1500 g/m2

- Subsequent web bonding is done by needling, stitch-bonding or spunlacing

Monofilament melt spinning

- Monofilament obtention from 90 dtex to 3500 dtex.

- Possibility of different geometries (flat tape, circular, trilobal, square, triangle, etc.)

- Possibility of biocomponent (Core-sheath, Side by side) and deferent geometries

- Production capacity from 0.5-4 Kg/h

Multifilament melt spinning

- Multifilament yarns with 24, 36, 72, 144 or 288 filaments from 100 dtex to 400 dtex (2-5 dtex/filament).

- Possibility of bicomponent (Core-sheath, Side by side, Segmented, Islands-in-the-sea)

- Production capacity from 10-12 Kg/h

- Possibility of post-processing techniques such as Air Texturing (TASLAN), Friction texturing process (DTY), twisting, fibre cutting (staple fibres), and open-end spinning process

Woven textile samples

- 50 x 200 cm woven samples of fabrics from a warp off a single bobbin.

- Until 22 +2 healds, for any ligament/density (warp and weft), double beam and 8 colors weft selection device.

- Possibility of obtaining functionalised textiles by using additivated fibres and other weaving/knitting techniques

Hot-melt laminator

- Roll to roll system, max. width = 25 cm

- speed: 1-20 m/min

- material deposition: 5-35 g/m2

Knife-coating (on air or on cylinder) system and padding (foulard) system

- Roll to roll system, max. width = 60 cm

- 2 drying and polymerization zones of 1.5 m each, T=30-200ºC

- Production capacity from 0.1-10 m/min

Spray cabinet

- Surface coating of fabrics and non-woven substrates

- Working area of 130cm x 130 cm with a suction system for fixing the substrate to avoid wrinkles during the spraying process.

Nanobubbles for finishing and dyeing

- Nebulization of liquid solution or nanodispersions forming nanobubbles wich interact with the fibers, impregnating the finishing product.

- Batch system

Benefits for SMEs and companies:

- Green chemistry approach

- More cost efficiency

- Environmentally friendly nanomaterials

- Technical trials at semi-industrial scale

Expertise and Capabilities:

- Injection of rigid packaging: injection moulding of test specimens and packaging

- Manufacturing of 3D-printed moulds by SLA

- Biopolymer filaments for 3D printing

- 3D printing of prototypes by FDM

Infrastructure:

- Filament maker (FilaBot EX6) to processcommodities (ABS and PLA), technical and high temperature/high viscosity materials (PA).

- Homemade 3D printer with control of temperature and moisture inside the printing volume.

Benefits for SMEs and companies:

- Feasibility analysis of customized filaments for 3D printing.

- Printing service by homemade 3D printer that allow avoiding some issues related with the hygroscopy of polymers and additives (tendency to water-absorption), and the warping issues due to temperature gradients on the printed parts.

- Prototyping of printed parts from customized filaments.

- Biomaterial cards in different softwares, obtained by characterization of printed specimens and mechanical/thermo-mechanical performance simulations.

- Minimization of post-processing waste

Expertise and Capabilities:

- Development of foaming formulations from bio-based polymers

- Extrusion foaming: high-density and low-density applications

- Bead-foaming: low-density bead foams

- Solutions for moulding beads to generate complex parts

Infrastructure:

- Extrusion foaming pilot plant:

- Single line with output up to 5 kg/h.

- Possibility of blending up to 5 blowing agents with precise dosage.

- Line fully instrumented to monitor pressure and temperature.

- In-line measurements of cellular structure and density.

- Bead foaming pilot plant:

- Capacity up to 1 kg/h.

- High pressure reactor to work with pressures up to 300 bar.

- Precise temperature control from -40 to 250 ºC.

- Possibility of working with different blowing agents and co-blowing agents.

- Lab-scale molding process to produce prototypes.

- Characterization lab:

- Climate chamber to set moisture and temperature conditions before testing.

- Thermal properties and rheological evaluation (foamability study).

- Mechanical properties and dynamic mechanical analysis.

- Acoustic absorption and fire resistance.

- Detailed analysis of the foam structure and evaluation of the relationship between process-structure-properties.

Benefits for SMEs and companies:

- Fabrication of foamed prototypes at lab-scale with low material consumption.

- Validation of polymers, additives and formulations intended for foaming applications.

- Characterization of foams and assessment of applicability.

- Specialized know-how in the field of cellular materials.

- In-deep analysis of the foam process.

Expertise and Capabilities:

- Produce coated flexible substrates with biobased functional liquid formulations: Roll-to-roll slot-die coating and roll-to-roll spray coating (cura UV)

- Flexo and gravure coating

- Nanofiber-based coatings by electrospinning employing biopolymers

- Spray coating on 2D and on 3D-shape substrates

- Paper and board coating by blade, rod and size-press

Infrastructure:

- Roll-to-roll spray-coating pilot line with different types of nozzles and configurations, and thermal or UV curing

- Roll-to-roll slot-die coating pilot line for application of coatings up to 300 mm of width

Specification of the roll-to-roll spray-coating pilot line at CeNTI’s facilities.

| Conveyor belt speed | 2 – 20 m/min |

| Nozzles | Ultrassound or anti-drip nozzles |

| Drying / Cure | Thermal or UV cure |

Specification of the roll-to-roll slot-die coater pilot line at CeNTI’s facilities.

| Coating Width | 300 mm |

| Line speed | 0-10 m/min |

| Coatings viscosity | 1 – 1,000 mPAS |

| Roll diameter | 500 mm (maximum) |

Rotary Koater at ITENE – Automatic printer, coater and laminator for flexible substrates papers, plastic films and metallic foils. This machine is versatile due to its interchangeable heads to perform flexographic, gravure and slot die applications. Besides two ovens for drying, it has also in-line corona treatment and UV curing.

- Width: 300 mm

- Speed: 0.5 – 5 m/min ; 5 – 50 m/min

- Surface treatment: corona

- Drying: max. 200ºC

- Curing system: UV curing

- Printing processes: flexography and gravure (theoretical vol. 10-50 cm3/m2)

Electrospinning pilot line for textile substrates up to 500 mm width with a capacity of nanofibers coating web between 0,5 and 15 g/m2.

Benefits for SMEs and companies:

- Coated products with functionalities and suitable for different applications, namely packaging, textiles, cosmetics and healthcare.

- Scalable and low environmental impact processes.

Support: (Non-)Technical Services

Process parametrization

Expertise and Capabilities:

- Energy dispersive X-ray fluroescence (EDXRF) techniques applied to inspection and monitoring of new materials or coatings

- Process optimization through simulation: advanced numerical simulation tools are used to optimize the design step considering the final applications

Expertise and Capabilities:

- Monitoring systems based in photonics enabling to upgrade the capabilities of targeted processes in terms of optimization, reliability and quality control

Expertise and Capabilities:

- Optimization of composites formulation and processing parameters

- Methodologies for nanocomposite virtual characterization

- Prediction of the properties of nanocomposites from their constituents

- Modelling of printing materials and simulation of 3D-printed parts behaviour

Route to market

- LCA measures and calculates the lifetime environmental impact of the product or service by both, the use of resources and the emissions created

- Life cycle cost assessment: economic evaluation of a product, service or an engineering project across its lifetime, which helps decision makers to choose the best investment plan, on the basis of the least cost.

- Social life cycle assessment (S-LCA): information on social and socio-economic aspects for decision making, in the prospect to improve the social performance of an organisation or a product and ultimately the well-being of associated stakeholders

- Definition of an integrated risk assessment approach (IATA) or nanobiomaterials

- Hazard profiling assessment services

- Exposure assessment services in work places

- Risk management services

- Definition of Safe-by-Design strategies for specific industrial cases

Expertise and Capabilities:

- Compostability analysis: material characterization, biodegradation, disintegration and compost quality

- Recyclability analysis of cellulosic products: test of recyclability according to EN13430 standard

Expertise and Capabilities:

- Assessment on the verification of compliance of any kind of food contact material

- Legislative vigilance

- Diagnosis and implementation of GMP standards

- Legal diagnosis/ supplier management

- Documentation and guidance for the authorization process of new substances for plastic materials

- Technical support for the authorization of recycled processes for plastic materials

Expertise and Capabilities:

- Market study to evaluate the potential

- Economic evaluation

- Risk analysis (to provide insight into the risk of the process for investors)

- Environmental analysis

Expertise and Capabilities:

- Regulatory compliance and advisory services (interpretation and implementation of regulatory requirements, legal design of business activities)

- Legal workshops on regulatory challenges and regulatory updates

- IPR management and protection: IP strategy & management, and IP advisory services

Expertise and Capabilities:

- Business model canvas applied methodology (branding and customer relationship management, pricing and sales, key activities and key resources, key partners and cost structure)

- Strategic workshops and webinars to presentation and networking in front of an audience of potential users

- Mentoring sessions and follow-up reports covering the most relevant aspects of a business according to the specific needs

- Market analysis to study the dynamics of a specific market (volume, value, potential customer segments)

- SWOT (strengths, weaknesses, opportunities, threats) and PESTLE (political, economic, social, technological, legal, and environmental) analyses