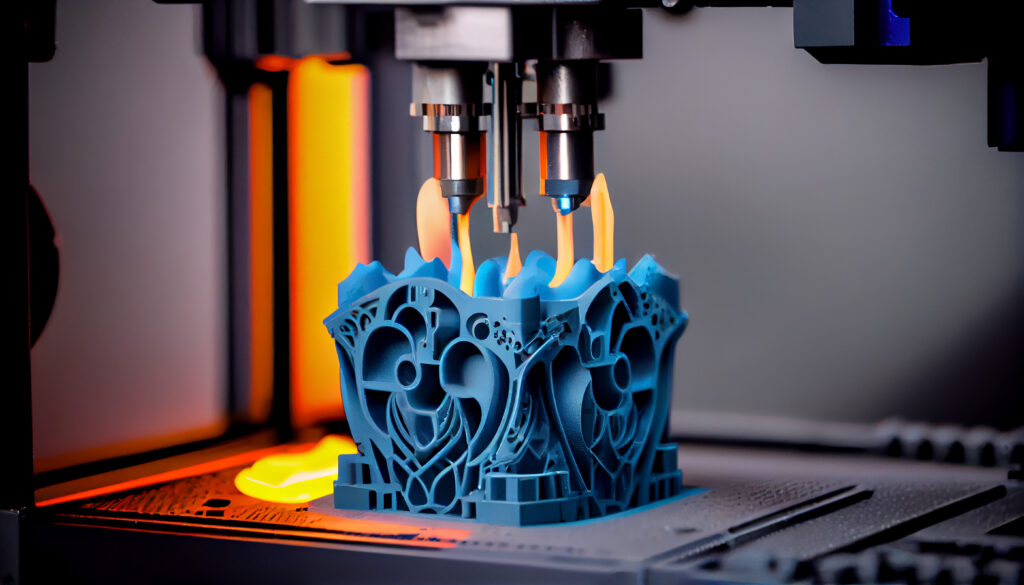

Harnessing 3D printing for sustainability

The intersection of 3D printing and sustainability is an extremely optimistic frontier in biotechnology and engineering. One of the key advances of 3D printing is that it reduces wastage of materials to near zero.

Practical Applications of Bionanomaterials

In the quest for sustainability, the rise of bio-based materials marks a significant shift towards a circular economy. Derived from renewable sources such as agricultural byproducts, plants, and microorganisms, these materials offer significant environmental benefits.

Join our workshop: Dedicated OITBs for Sustainable Bionanomaterial Production

The two OITB projects BIOMAC and Bionanopolys organize a joint stakeholder workshop at esib 2024 in Graz, Austria. Get part of it and learn about use cases in the bionanomaterial field!

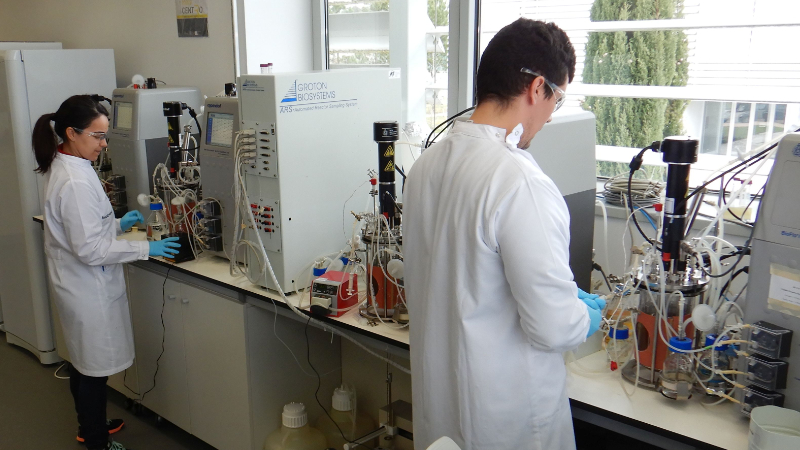

Biotrend: Experts in Fermentation Process Development, Optimization and Scale-up

A key pillar for a sustainable future lies in conserving fossil resources by replacing them with biomaterials which hold great potential as an alternative. Enhancing the functional properties of these biomaterials is essential for their competitive edge in the market…

Ensuring Safety and Compliance: The Cornerstone of Innovation in BioNanoPolys

A key pillar for a sustainable future lies in conserving fossil resources by replacing them with biomaterials which hold great potential as an alternative. Enhancing the functional properties of these biomaterials is essential for their competitive edge in the market…

Shaping the future: The Bionanopolys project’s influence on the bio-based material market

A key pillar for a sustainable future lies in conserving fossil resources by replacing them with biomaterials which hold great potential as an alternative. Enhancing the functional properties of these biomaterials is essential for their competitive edge in the market…

Green Chemistry and Biotechnology Innovations in Cosmetics: AmbrosiaLab’s Journey with Bionanopolys

Ambrosialab is dedicated to the innovative development and formulation of new ingredients for cosmetics and medical devices. The focus is particularly on valorizing ingredients emerging from green chemistry and biotechnology, employing cutting-edge formulation techniques. The Bionanopolys OITB allows us to join a network of partners with skills complementary to ours and to expand our knowledge and expertise…

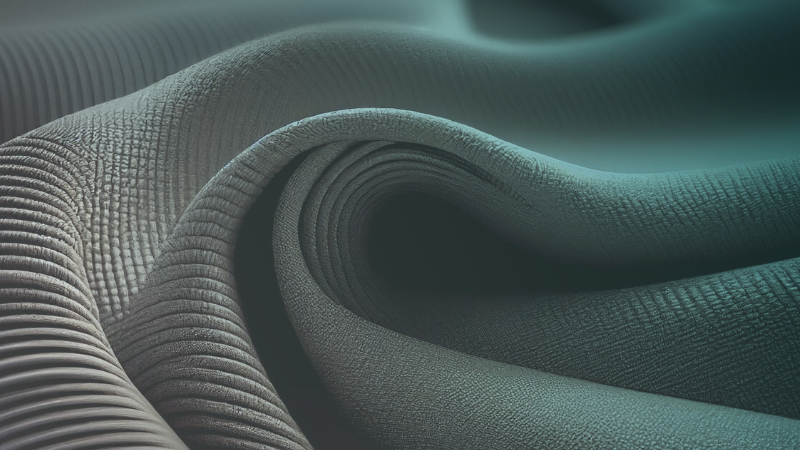

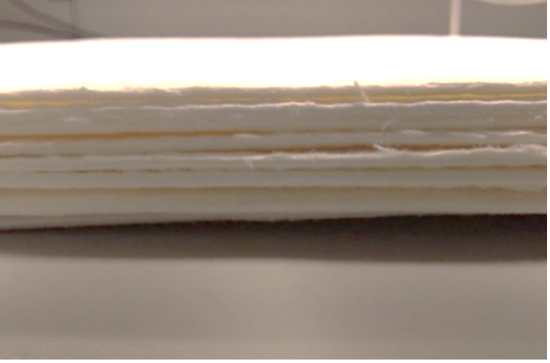

Textiles and non-woven fabrics – a Bionanopolys application field!

The participation of AITEX and STFI in BIONANOPOLYS project is focussing on the textile sector providing our broad experience to develop innovative and eco-friendly products by offering pilot plants available in the BIONANOPOLYS portfolio.

How to tackle the challenge of upscaling biomass pretreatment for bionanomaterial production

Bio Base Europe Pilot Plant (BBEPP) is an independent, state-of-the-art facility that operates from laboratory level to multi-ton scale. Bio Base Europe Pilot Plant is a service provider for process development, scale-up and customised manufacturing of bio-based products and processes. A wide and flexible spectrum of modular unit operations combined with the experience of our highly competent engineers and technicians enables us to turn your biobased laboratory protocol into a viable industrial process.

The six companies selected in the BioNanoPolys open call gain access to the OITB’s services

It is a pleasure to share the latest news on the BioNanoPolys project, in which we have been working tirelessly to promote innovation in bio-based nanomaterials. A significant step has been taken this September with the start of the implementation of the six projects selected in the Open Call.

We are particularly pleased with the response we received to this call.